Custom Brass Signs for Elegant Business and Home Décor Improvements

- The Sign Company UK

- 3 days ago

- 5 min read

You can make a strong first impression with a custom brass sign that reflects your style and purpose. Whether you want a polished plaque for a business entrance, a heritage-style nameplate for your home, or a bespoke piece for an event, a well-crafted brass sign communicates quality and permanence.

Custom brass signs offer durability, timeless appearance, and full customisation to match your exact needs. You’ll learn how to choose the right finish, size and lettering so the sign works for its setting and lasts for years.

Key Takeaways

Custom brass signs provide a high-quality, long-lasting presentation.

Options like finish and engraving determine the final look and suitability.

Choosing the right size and style ensures the sign meets your purpose.

Overview Of Custom Brass Signs

Custom brass signs offer durable, polished signage with options for finish, fixing and engraving to match your brand or space. The sign company provides choices in thickness, mounting, lettering style and protective coatings that affect longevity and appearance.

Types Of Brass Signs

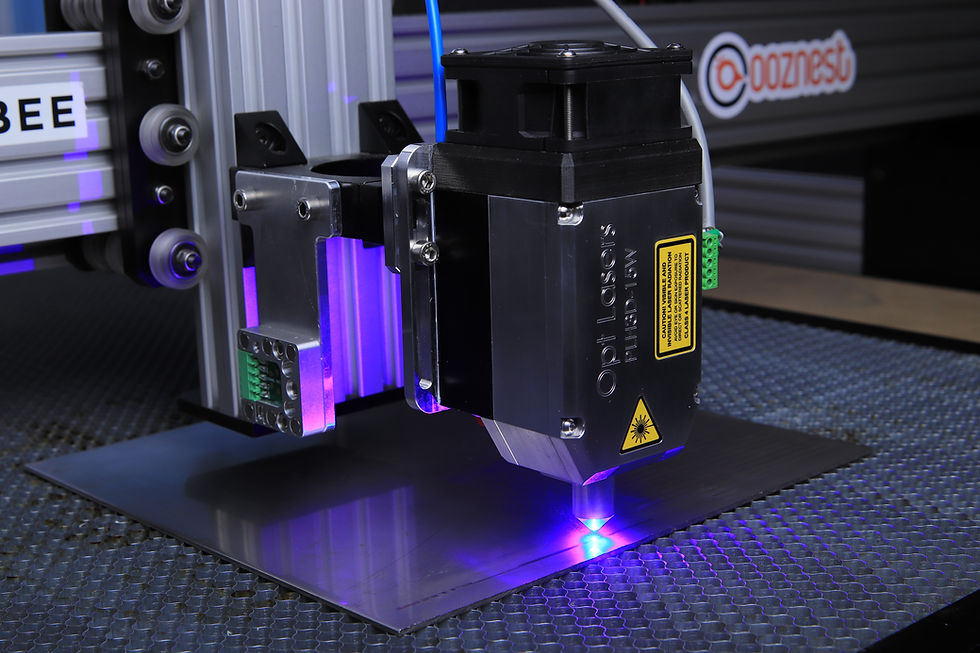

Brass signs come in cast, engraved, etched, and printed varieties, each suited to different budgets and aesthetics. Cast signs use molten brass poured into a mould for a three-dimensional effect; they work well for plaques and heritage markers where depth and detail matter. Engraved signs involve CNC or laser removal of material from a brass plate, producing crisp letters that you can backfill with paint for contrast. Etched signs use chemical processes to create textured recesses ideal for subtle, high-end signage. Printed brass combines a brass substrate with UV or screen printing for full-colour logos and photographic detail. Thickness typically ranges from 1mm to 6mm; choose thicker plates for exterior use or where impact resistance matters.

Benefits Of Customising Brass Signs

Customisation lets you control durability, finish and legibility to match your environment and brand guidelines. Selecting a matte, satin or high-gloss finish affects glare and maintenance; lacquered or clear-coated options add weather resistance for outdoor installations. You can specify font size, letter spacing and contrast to meet accessibility requirements such as minimum character height for wayfinding. Custom fixings—such as stand-offs, backplates or security screws—determine whether signs sit flush, float or resist tampering. Personalised details like corporate logos, serial numbers or QR codes increase professionalism and traceability.

Common Applications Across Industries

Hospitals, hotels, law firms and government buildings commonly use brass signs for permanence and a professional look. In healthcare, you’ll find room IDs and compliance plates made to hygiene standards with easy-to-clean finishes.

Hospitality uses engraved door signs, table numbers and reception plaques that match interior design and brand palettes. Legal and professional services prefer brass nameplates and directory signs to convey trust and longevity.

Manufacturing and utilities use brass for durable equipment labels, calibration plates and hazard signage where resistance to oils and solvents is essential. Heritage sites and memorials favour cast brass for longevity and historical authenticity.

Popular Design Options

Design choices influence both aesthetics and function, so specify colour fills, edge treatments and mounting early in the design stage. Colour fills (enamel or paint) increase legibility; common colours are black, white, navy and brand-specific Pantone matches. Edge options include bevelled, straight-cut or hand-polished edges for a refined look. Mounting choices—pin mounts, adhesive pads, magnetic mounts or rivets—affect installation method and substrate compatibility. Surface treatments such as antiquing, brushing or mirror polishing change the perceived age and reflectivity of the sign. You can add tamper-proof fixings, anti-graffiti coatings or anti-tarnish plating depending on exposure and security needs.

Choosing The Right Custom Brass Sign

Decide which appearance, engraving method and mounting will meet your location, budget and maintenance expectations. Think about durability, legibility and how brass signs will interact with light and weather where you plan to install them.

Selecting Materials And Finishes

Brass alloys vary by copper/zinc ratio; choose C260 (70/30) for classic colour and good corrosion resistance, or C360 (free‑cutting) if you need fine machined details. Thickness matters: 1.5–3.0 mm suits indoor plaques; 3.0–6.0 mm works for exterior signs that must resist bending and vandalism.

Finish affects look and upkeep. Polished (mirror) brass gives a bright, formal appearance but shows fingerprints and oxidises faster. Satin or brushed finishes mask wear and need less frequent cleaning. Lacquered brass keeps that fresh look outdoors for several years but will eventually require re‑coating; unlacquered brass develops a natural patina that protects metal and can be desirable for heritage projects.

Consider backing materials for composite stability: aluminium honeycomb or acrylic backing prevents warping on large brass signs. If you need reflectivity or high contrast, add a stainless steel or black enamel backing. Specify marine‑grade options for coastal installations to reduce verdigris.

Custom Engraving Techniques

Mechanical engraving uses rotary cutters or V‑bits to remove material and create deep, tactile lettering. It gives high durability and is ideal for raised filled lettering or when you want paint or enamel insets. Specify cut depth — typically 0.8–1.5 mm for visible contrast — and choose chamfered or square‑bottom cuts depending on the style you want.

Laser engraving ablates the surface for fine detail and photographic reproduction, but it produces less depth and can be less legible at distance. Combine laser with chemical etching to create two‑tone effects. Chemical etching (acid etch) produces uniform depth across complex shapes and suits batch production; it pairs well with hand‑applied patinas or lacquer fills.

Consider inlay and enamelling for long‑term colour retention. Powder‑filled engraving is durable and offers colour matching (RAL or Pantone). Request sample swatches or a small prototype from The sign company to confirm legibility, fill adhesion and the interaction between finish and lettering under the actual site lighting.

Brass signs from The sign company are an investment in both style and practicality. With the right choices in material, finish, and engraving, your brass signs will stand the test of time and add a touch of elegance to any setting. For businesses and homes alike, The sign company offers expertise to help you design and install the perfect custom brass signs for your needs.

Be sure to read our related blogs on brass signage letters and What Are Brass Signs Used For? to learn more about their versatility and design impact.

Installation Considerations

Select mounting hardware based on substrate and security needs. For brick or masonry, use anchor bolts or sleeve anchors; for timber, use countersunk stainless steel screws. Use stand‑offs (25–50 mm) to add depth and shadow for improved legibility on brass signs read from a distance. For accessible signage, ensure character height and contrast meet local building codes and wayfinding standards. The sign company recommends these guidelines for all brass signs to ensure maximum visibility.

Weatherproofing matters: seal drilled holes and use stainless or brass fixings to prevent galvanic corrosion. For external brass signs exposed to strong winds, calculate wind load and use additional fixings or a reinforced backing plate. If you plan flush mounting on fragile surfaces, employ adhesive systems rated for exterior use and test adhesion on a small area first. The sign company suggests always considering weather conditions when installing brass signs.

Think about maintenance access. Mount brass signs with removable fixings if you expect periodic re‑lacquering or cleaning. Label orientation, reading height, and line‑of‑sight from primary approaches before final drilling to avoid costly relocations. The sign company can provide guidance on the best installation practices for your brass signs.

Comments